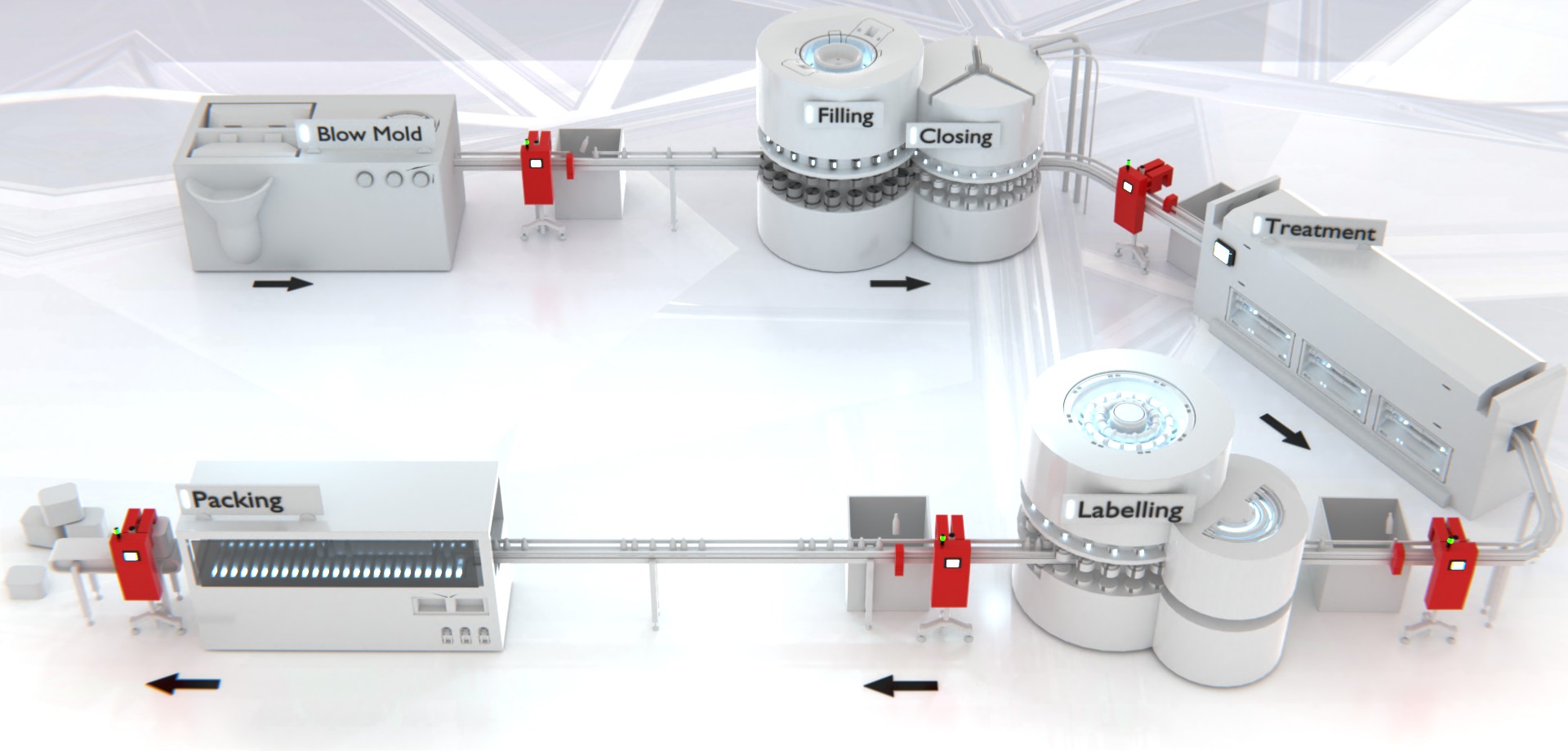

Inspection & Rejection After Unpacking

Empty Can Inspection

Empty can inspection systems prevent damaged cans from reaching the filler and check for correct cans as well as imprints and labels .

Inspection

Rejection Systems

Inspection & Rejecion After Filling/Closing

Fill Level- & Cap- Inspection

Fill level and cap inspection systems prevent bursting and guarantee tightness of the bottles after filling.

Inspection

Rejection Systems

Inspection & Rejection After Treatment

Leakage Inspection

Inspection to prevent leaking containers being packed.

Inspection

Rejection Systems

Inspection & Rejection After Labelling

Label- Inspection

Inspection system after the labeler always guarantee the correct labels, checking imprints for correctness and perfect fit.

Inspections

Rejection Systems

Inspection & Rejection After Packing

Full Crate Inspection

Inspection system for full crates after the packer. Prevents incomplete crates from being delivered.

Inspection

Rejection Systems