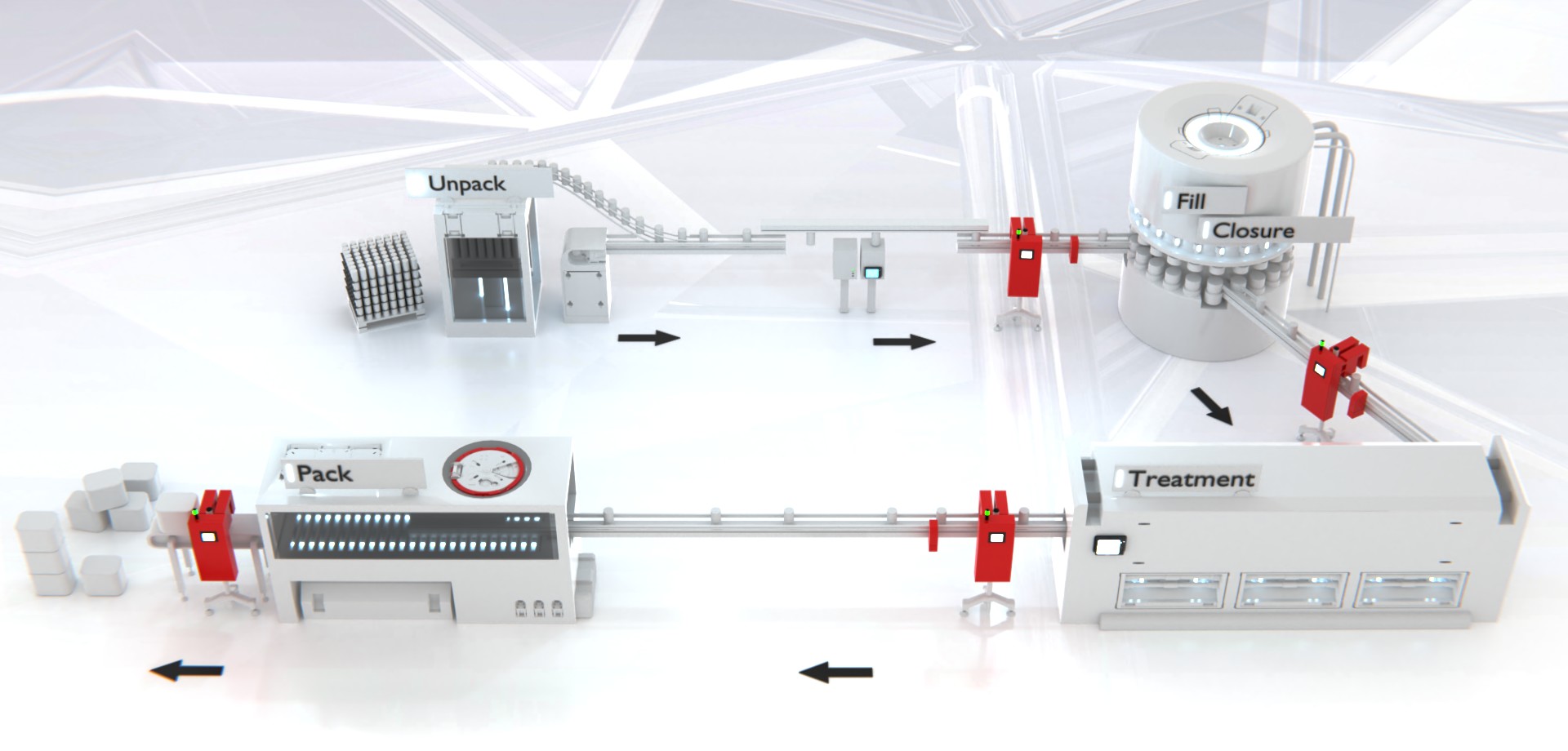

Inspections & Rejections Before The Filler/Closer

Empty Can Inspection

Empty can inspection systems prevent damaged cans from reaching the filler and check for correct cans, imprints and layouts.

Inspection

Rejection Systems

Inspections & Rejections After The Filler/Closer

Fill Level Inspection

Inspection systems for fill level inspection guarantee properly filled cans. And thus avoid bursting (in case of overfilling) or complaints (in case of underfilling).

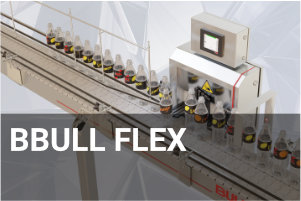

Inspection

Rejection System

Inspections & Rejections After Treatment

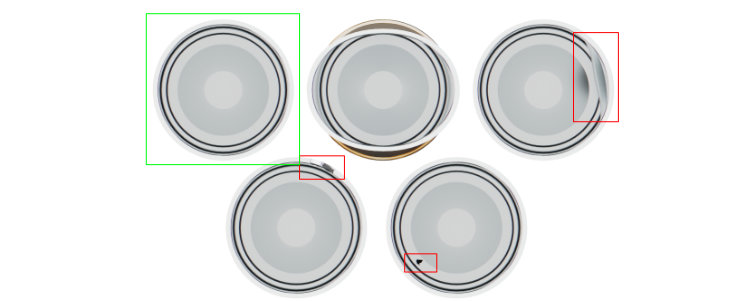

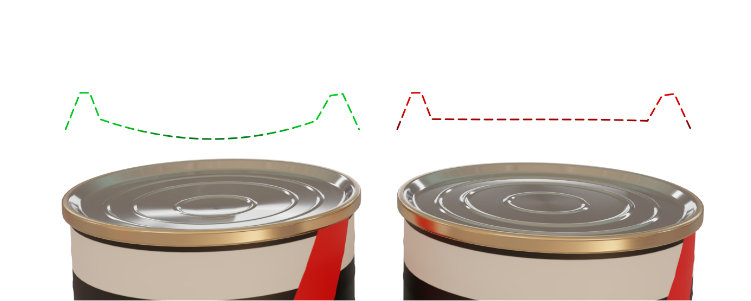

Leakage/Cap Inspection

Leakage checks guarantee properly sealed cans and thus avoid leaking containers and stale products.

Inspection

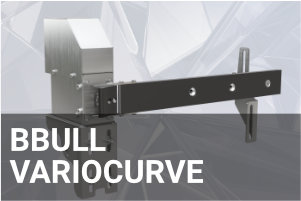

Rejection System

Inspections & Rejections Before The Packer

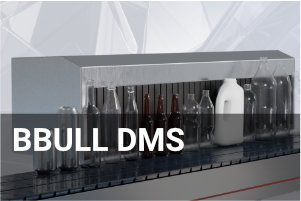

Full Crate Inspection

Full crate inspection systems check completeness in trays, sixpacks, crates & other containers. And detect not only missing but also empty cans.

Inspection

Rejection Systems