Customized closure checks: your seal of quality

In production, every detail counts, especially the closure. It is our first promise of quality and safety. At BBull Technology, we understand the distinctiveness of each project and offer customized closure control solutions.

BBULL ALPHA CIS

Cap inspection via proxy or laser, reliably detects slanted or damaged caps.

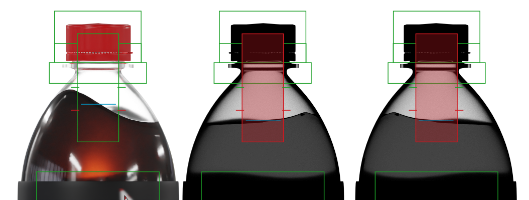

BBULL IMAGE APA

A camera inspection system specifically designed to detect the application angle of screw caps. This enables us to prevent over-tightened or too tightly closed bottles.

BBULL ALPHA MAS

Sound and proxi based closure inspection specifically for metal closures. Detects not only damaged or slanted closures, but also leaks.

BBULL IMAGE 120

Multi-camera system inspects closures from all sides and detects not only smileys or slanted sits, but also lid color and optionally fill level and label presence.