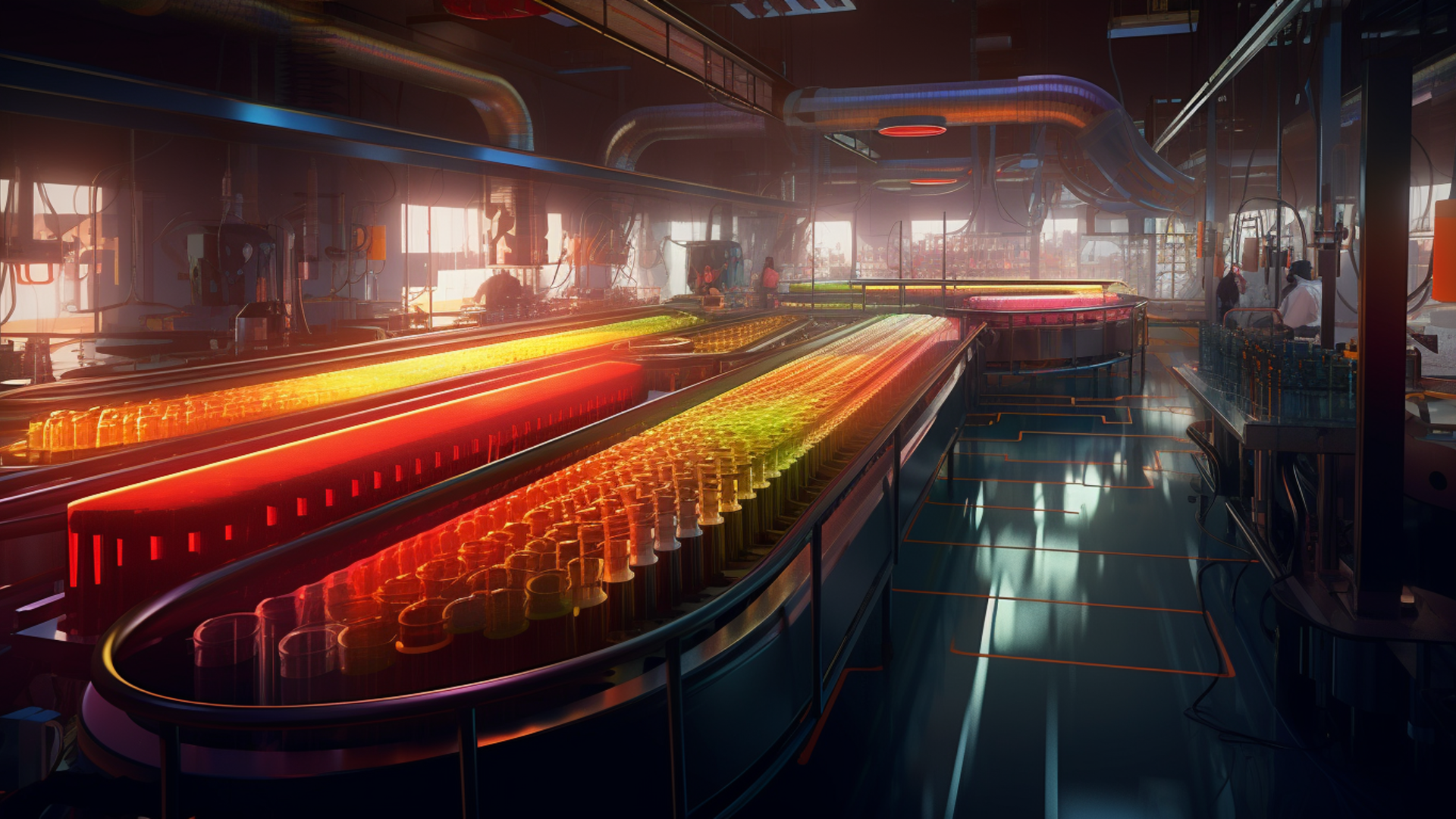

A cost-efficient and simple solution for exceptional cap inspection in your production line. With its high-resolution sensor and precise guidance, this system reliably detects defects and improperly applied caps.

Easy to set up and train, it enhances quality control, improves efficiency, and reduces waste. Experience increased customer satisfaction and data collection for process optimization. Making it a valuable addition to your production line.

Designed to work with various metal caps and containers, the ALPHA CIS Cap Inspection System ensures the highest quality standards for your products.

Multiple Benefits

Enhanced quality control

Identify faulty or improperly sealed containers within the production process. Improve product quality and safety while meeting regulatory standards.

Improved efficiency

Automate cap inspection, reduce labour costs and improve production efficiency. Reduce manual inspection and sampling to a minimum.

Reduced waste

Remove faulty containers early, reducing waste and production costs. Act quickly when problems accrue to avoid product and material waste.

Increased customer satisfaction

Improve product quality and customer satisfaction, building brand loyalty.

Data collection and analysis

Enable data collection and analysis to optimize production processes, improving efficiency and quality.

What can we inspect?

- Cap Integrity

- Damage

- Deformations (bull nose caps)

- Fit

- Absence

- Vacuum

- Missing vacuum

- Pressure

- High pressure

- Missing pressure

Metal Caps

- Jars with twist-off caps

- Bottles with crown cork and other metal caps

- Beverage Cans

- Food Cans

How does it work

The CIS (Cap Inspection System) uses a proximity sensor to check if caps or lids are properly applied and sealed. Measuring the height of the cap/lid along the full cross-section to see if it matches the set values, and removes faulty containers early from the production process.