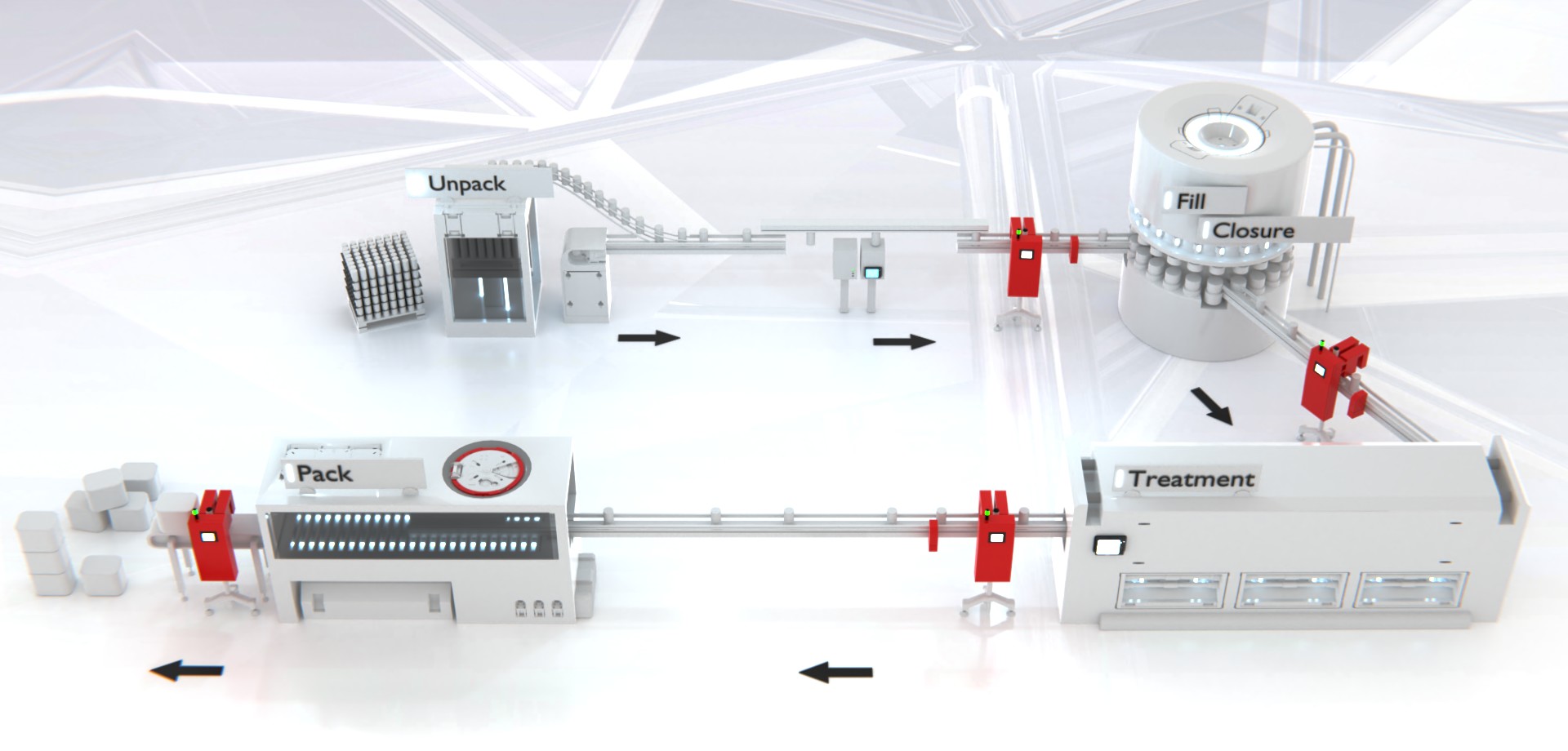

Inspections & Rejections Before The Filler/Closer

Empty Can Inspection

To guarantee that no deformed, damaged or contaminated cans reach the filler empty can inspection is a necessity. Providing safety to customer by rejecting contaminated cans before filling, as well as preventing damage to filler / closer due to irregular seams and damaged or leaking cans.

Inspection

Rejection Systems

Inspections & Rejections After The Filler/Closer

Fill Level Inspection

Detecting underfilled cans helps to achieve authorities and quality standards and rejecting of potential leaking and underfilled cans. The detection of overfilled cans helps to save product and to prevent can burst events by rejecting them early from production.

Imprint/Code

Finding and verifying date and 2D / QR codes guarantees to meet legal requirements, verification of correct label and enables tracking of every container from filling to the retail shelf.

Management

Collection and combination of data from filler / closer / labeller as well as inspection systems provides important data to optimize the production process, to schedule sampling and preventive maintenance and to manage rejections on container burst or high air (loss of CO²/LN² in the headspace by conveyor downtimes).

Inspection

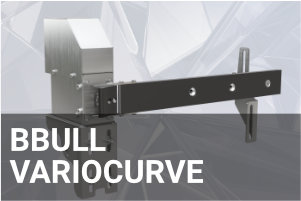

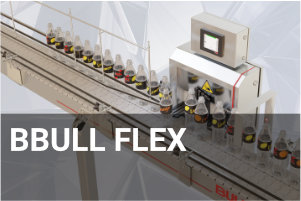

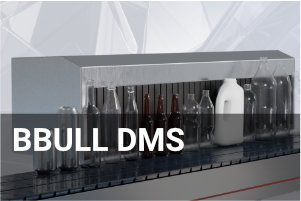

Rejection System

Inspections & Rejections After Treatment

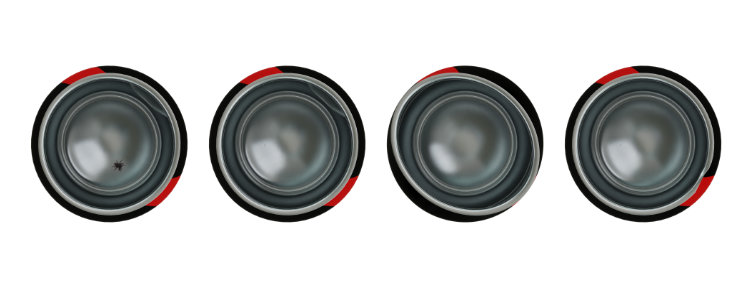

Leakage Inspection

Special designed leakage detection with the advantage of high accuracy on high production speeds to ensure that poor sealed or pressure less cans are removed from production to prevent reputation damage and expensive recalls.

Inspection

Rejection System

Inspections & Rejections After The Packer

Full Crate Inspection

The end of line full crate/pack inspection is essential to guarantee that every crate reaching the customer is packed with the proper amount of accurate filled containers.

Inspection

Rejection Systems