BBULL IMAGE LG-DL

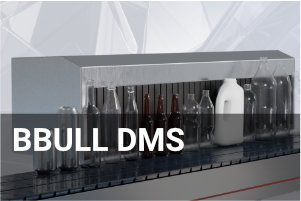

Prevent damage and downtime with BBULL’s Empty Crate Inspection systems. Our advanced technology accurately identifies the contents of each crate before it reaches the unpacking system, providing valuable data for efficient and effective processing. Our rejection systems also handle the removal of foreign or problematic crates, ensuring a smooth and uninterrupted flow for the unpacking machine. Trust BBULL for reliable and efficient Empty Crate Inspection.

Tasks

- Unpackability check

- Interspace control (foreign object detection)

- Foreign objects above the bottles

- lying bottles

- fliped bottles

- Broken bottles

- Bottle counting (detection of missing bottles)

- Detection of residual caps on the bottles

- Bottle sorting based on

- Bottle material (glass/PET)

- Bottle diameter/height

- Bottle contour/colour

- Neck labels

- Closure type (swing stopper, neck ring)

- Closure material (glass / PET)

- One-way / reusable PET

- Crate sorting

- Format (L x W)

- Compartment type (modular / honeycomb)

- Conveyor flow direction

- Colour

- Logo

- Damages

- Deformations

Features

- Self-adaptive algorithms

- Easy teach-in through TEACH-IN procedure

- For complex tasks

- Flexible / scalable

- Detailed statistics

- Very compact design

- Minimal space requirement