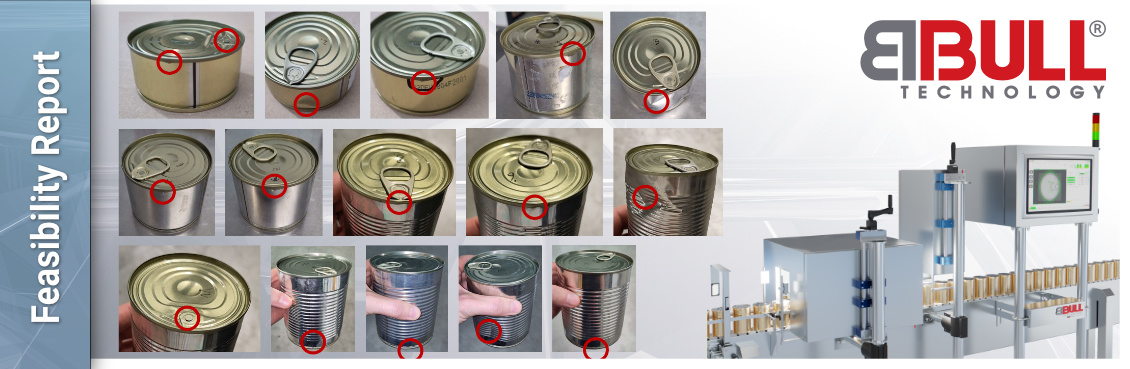

Inspecting a pool of 15 damaged food cans containing the most commonly damage types, occurring during the filling and seaming process.

The System

The inspection system consist of two inspections units covering the top and the sides of the can.

A control unit with high performance industrial PC and a Deep-Learning software package.

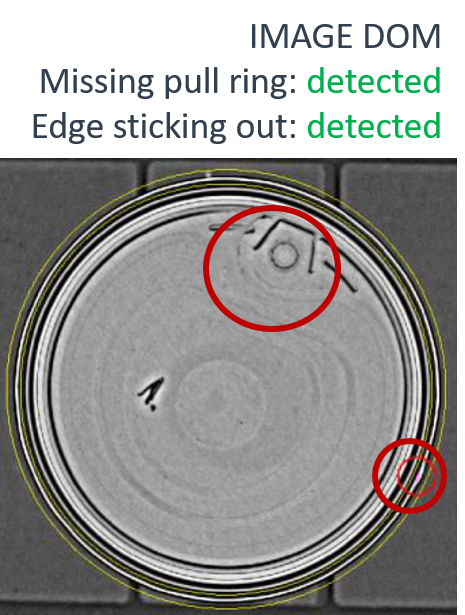

- One camera with diffuse light from above. Top-Down Inspection (Image Dom)

- Ovality

- Damage

- Missing pull ring

- Four cameras for a 360° view of the sides. Side Inspection (Image 360)

- Damage

- Dents

Deep-Learning

With deep learning based classification, it is possible to detect errors visible to the human eye without needing to configure complicated inspection tools.

Instead, images of OK and not OK objects are collected and used to train a classifier, which will then be able to safely distinguish OK and not OK objects.

Example

Summary

All damage types could be detected successfully ether via top-down is section, or side inspection.

We therefore have a flexible system for the reliable detection of frequently occurring damage types.

Which can be scaled according to the requirements of the customer.

Deformed cans are detectable without deep-learning, sticking out material on the other hand might need the deep-learning algorithm.

In this case, deep-learning and both inspections systems were needed to detect all occurring defects.